Our strengths

Mould workshop

At the heart of our expertise is an automatic embossing and welding machine, designed specifically for EUROPAFI and commissioned in 2017. But it is above all the designers and engravers who bring this workshop of excellence to life. Their expertise, attention to detail and mastery of traditional and modern techniques enable them to create unique watermarks of unrivalled finesse and precision. Each mould is the result of meticulous craftsmanship combined with new technologies, guaranteeing results that meet the highest standards of security and aesthetics.

Fibre preparation

Our fibre processing line has been completely redesigned to guarantee impeccable product quality:

- In 2017, a new milling machine was installed, accompanied by a latest-generation contaminant detection and cleaning system, ensuring the cleanliness of the cotton before it passes through our Bivis system.

- Since 2023, a new-generation cylinder mould machine, equipped with its own refining circuit, now allows us to process all types of fibre with remarkable consistency.

Behind our state-of-the-art equipment are experienced operators who ensure optimal processing of raw materials. Their expertise and rigour ensure optimal fibre preparation, guaranteeing consistent quality throughout the manufacturing process.

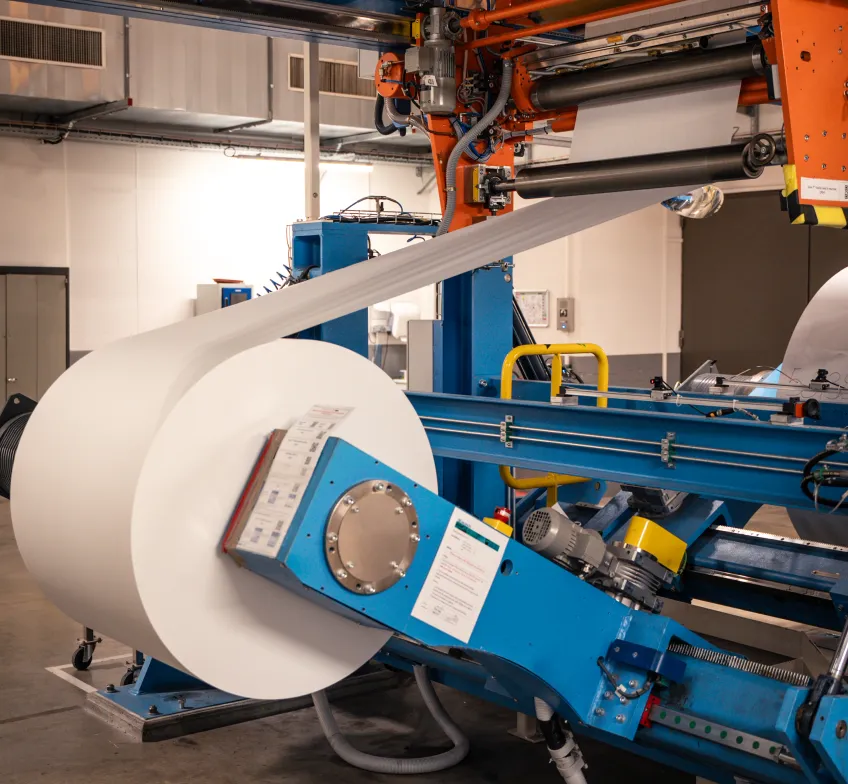

Paper machine

Jointly developed by Voith and Allimand , our paper machine produced its first sheets in 2017. Designed to offer exceptional precision and reliability, it manufactures reels that meet the most stringent requirements in terms of safety and product quality.

But this performance is based above all on the expertise of our paper makers, who operate the machine with constant vigilance. Thanks to a state-of-the-art visual inspection system and the most advanced technological innovations in marking and traceability, they guarantee a finished product that meets the most demanding standards.

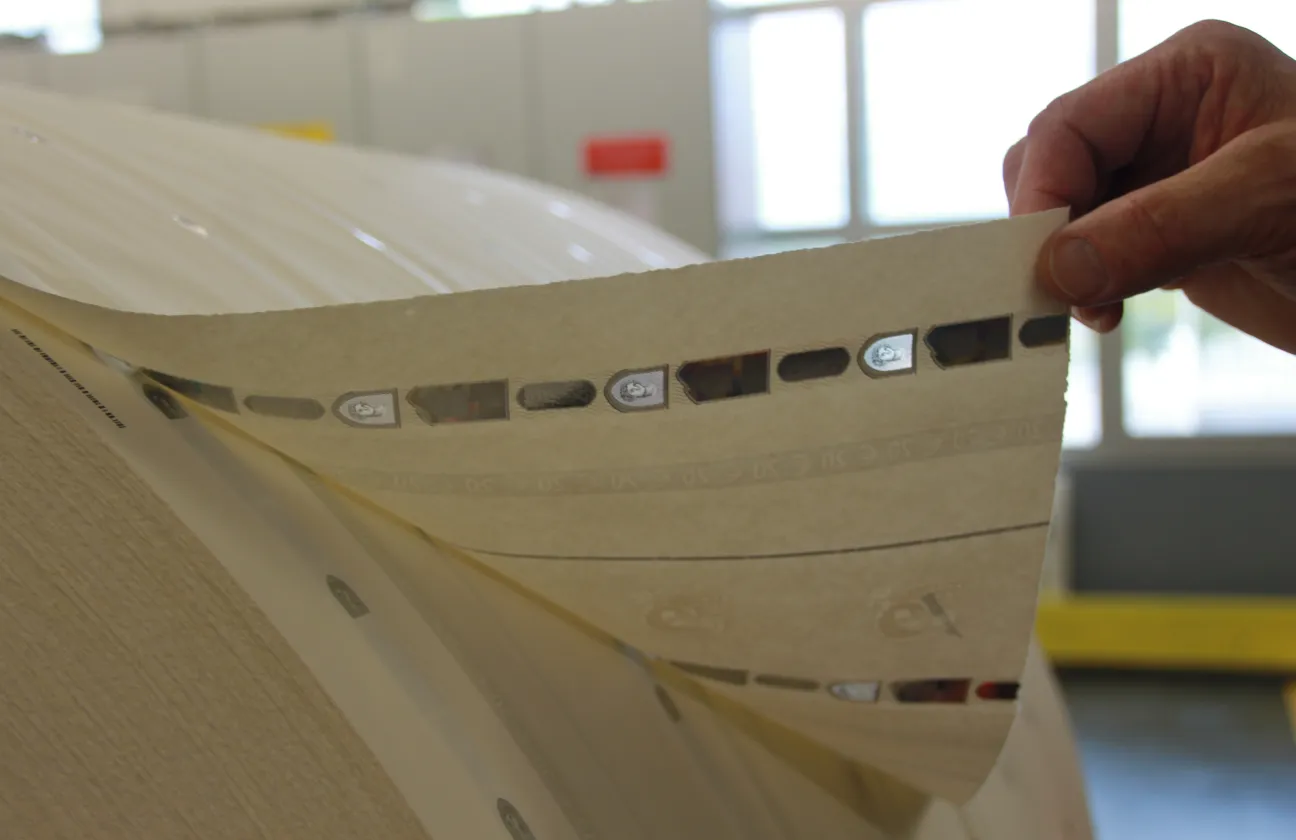

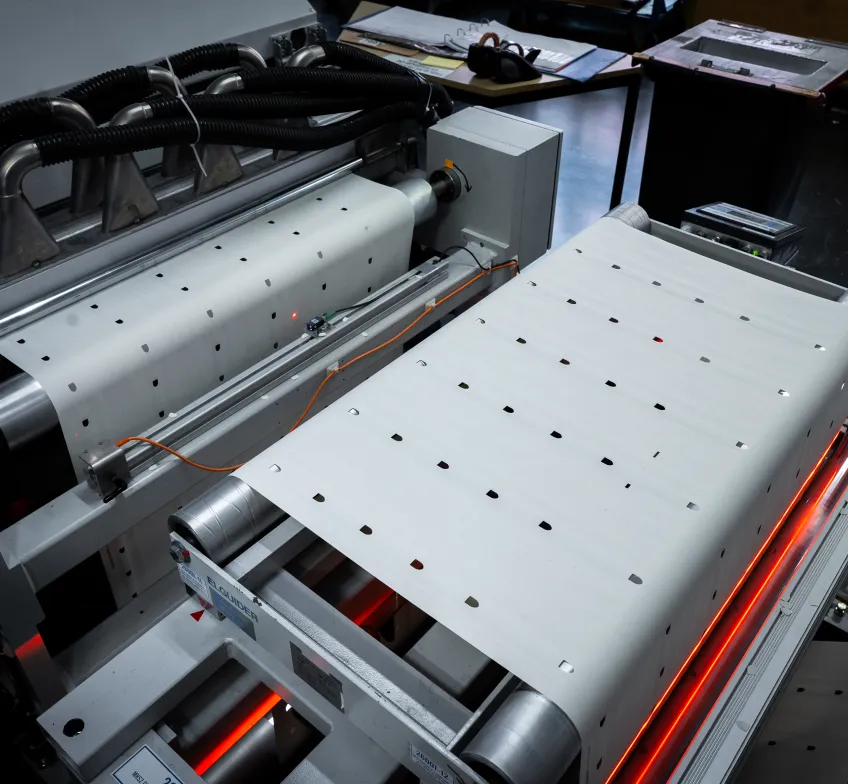

Security machine

Security goes hand-in-hand with precision with our two Kurz security machines, equipped with :

- Advanced motorisation and speed control technologies

- Integrated screen printing unit

- Cutting module

- Two integrated hot-stamping holographic strip application units

The attention to detail and technical expertise of our security operators ensure the smooth integration of sophisticated security features, while maintaining the speed and performance of the most demanding machines.

Cross-cutter

Installed in 2016, our Pasaban cross-cutting machine is equipped with a state-of-the-art quality control system, ensuring that each sheet meets our highest standards before dispatch. It is operated by highly qualified finishing staff, whose keen eye and rigour ensure meticulous inspection, precise adjustment and validation in accordance with EUROPAFI's criteria of excellence.

Research and Development

Our modernisation programme perfectly illustrates the importance of research and development (R&D). At EUROPAFI, R&D means investing in industrial innovation and new technologies in order to continuously improve our equipment, processes and product quality.

Industrial innovation and excellence

At EUROPAFI, every investment reflects our commitment to excellence and innovation. Every machine, every improvement, every technical action is designed to achieve our goal: to produce banknote paper that sets the global standard, combining technological innovation, machine performance and product quality.